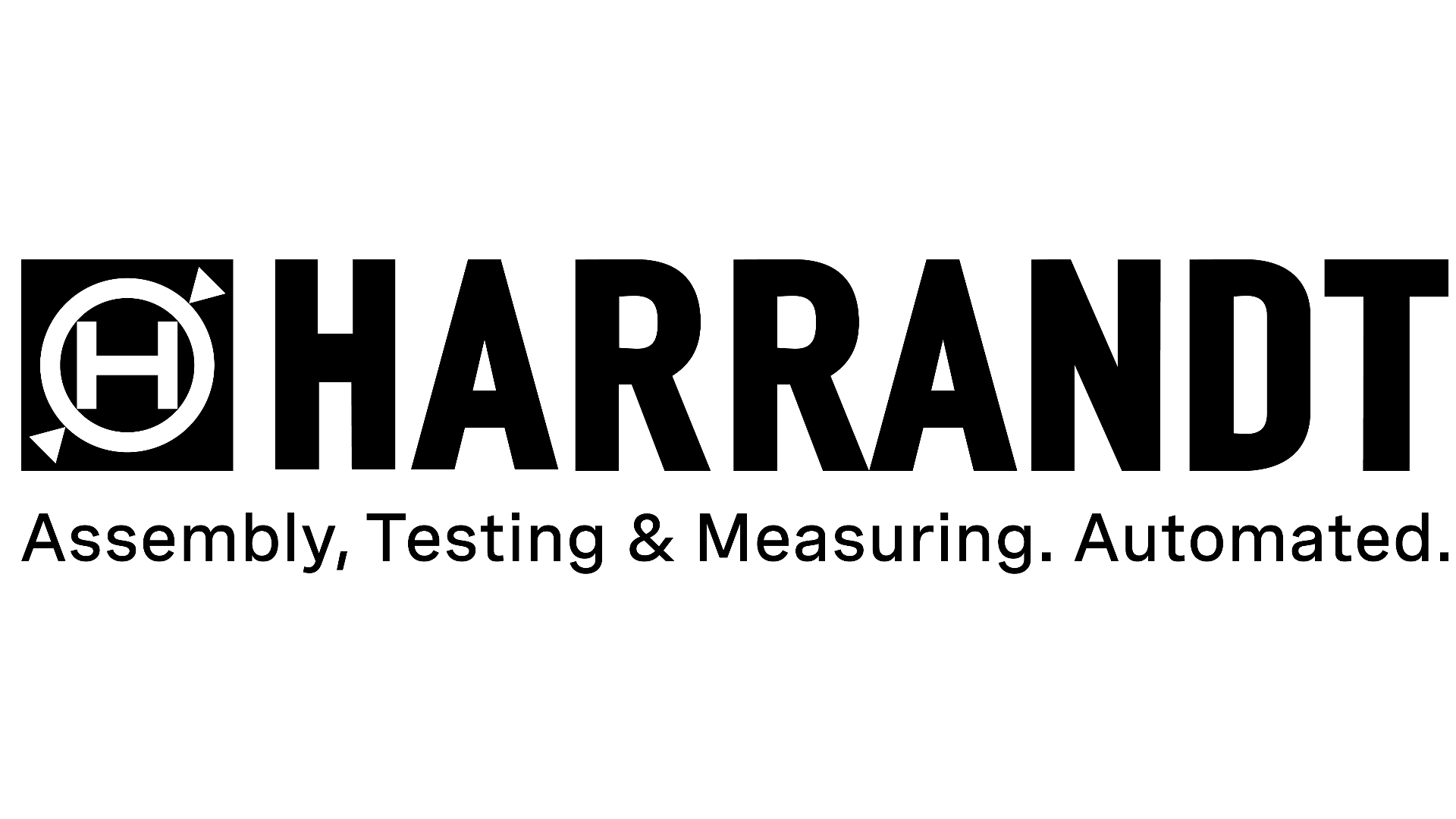

Our assembly lines are equipped with advanced sensor systems that detect errors in real time, significantly increasing process reliability. This ensures consistently high quality and reduces scrap. Particularly sensitive components are joined gently through precise control of force, position, and speed to avoid mechanical overload and damage. Thanks to our modular, robot-assisted systems, new components can be quickly and flexibly integrated into the assembly process, enabling future-proof production.

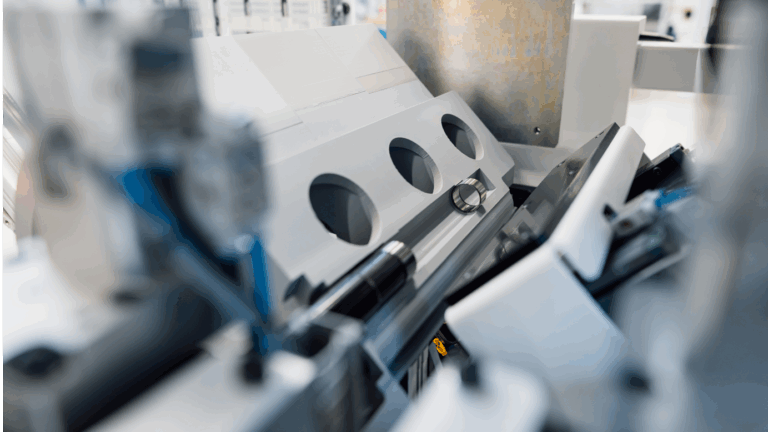

By using intelligent robotics solutions, we implement precise and fast pick-and-place processes that ensure optimal material feeding and increased production output. Our robot systems also integrate automated spot taping applications to reliably secure components, increase process reliability, and minimize manual effort.

With our many years of experience in the development and implementation of automated assembly lines, we offer customized solutions for demanding manufacturing processes. From design and the integration of intelligent robotics to quality assurance, we focus on the highest levels of precision, efficiency, and process reliability to provide our customers with innovative and high-performance automation solutions.