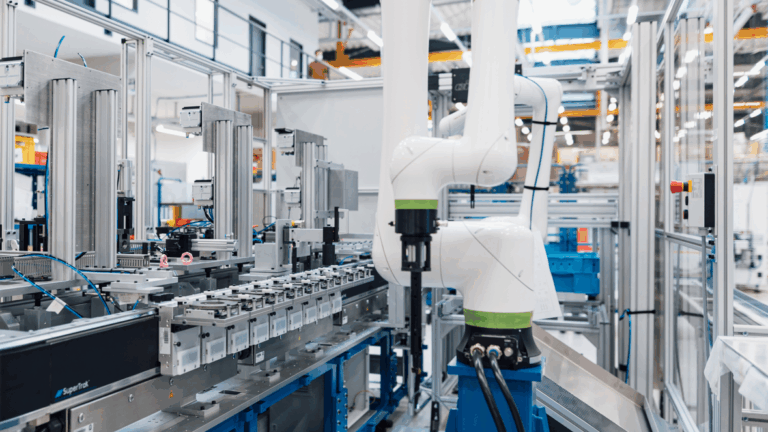

For the assembly line, which was designed, built, and successfully commissioned by Feinwerktechnik Otto Harrandt GmbH, we relied on components from leading manufacturers.

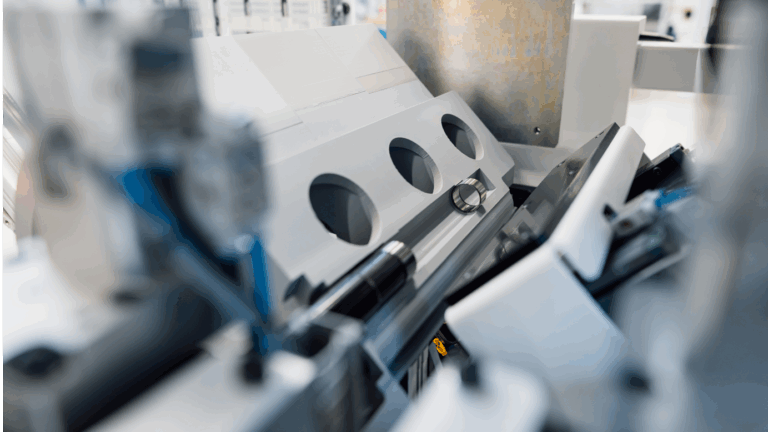

The heart of the assembly line are the 30 workpiece carriers, on which a total of five different high-performance engines can be processed in one cycle time.

The Harrandt assembly line is also capable of handling up to eight different engine variants without additional setup procedures or workpiece carrier changes.

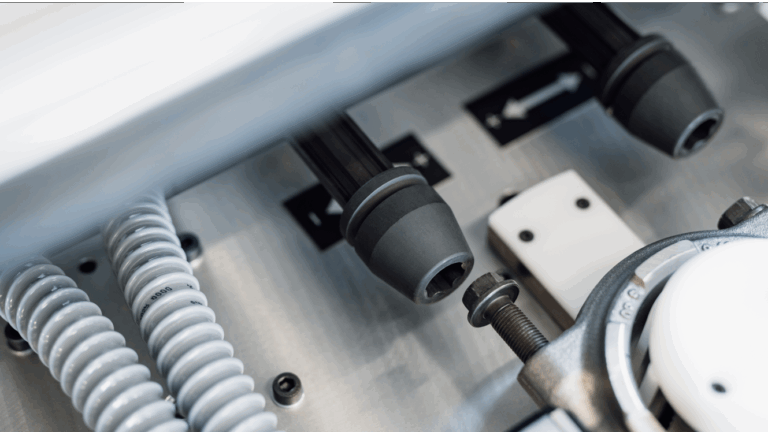

The servo axes offer highly dynamic motion sequences and guarantee precise positioning. The transfer system ensures a smooth material flow, while door safety switches and sensors guarantee maximum safety and precision.

The safety components – fences and protective covers – and the pressure-sensitive mats provide the necessary safety precautions to meet the requirements of a modern production environment. A DMC scanner is used for optical quality control, enabling complete traceability and also checking the correct combination of piston and connecting rod. The entire system is controlled by the proven Siemens PLC, which, in conjunction with the high-precision gripper and all other components, ensures smooth automation. The system is rounded off by innovative lubrication systems.